Application:

Petroleum & Petrochemical

Pressure Vessel

Electric Power Construction

Stainless Steel Product

Processes:

DC TIG

MMA(Stick)

Advanced Features

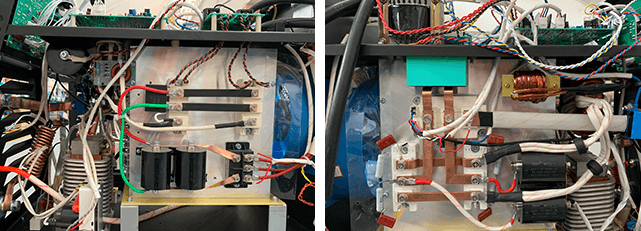

Powerful and Reliable at heavy industrial level

This unit is a 3-phase TIG welder equipped with latest IGBT modules, which ensures a powerful output 500A@100% duty cycle. It is also equipped with an integral cooling unit, providing efficient cooling for liquid-cooled torches in high duty production welding environments. With the shape of the arc, weld penetration, cleaning effect, as well as the other features are under precise control, and ensuring that the quality of the welds remains high at every level.

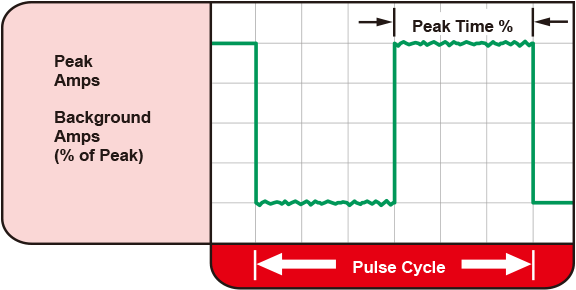

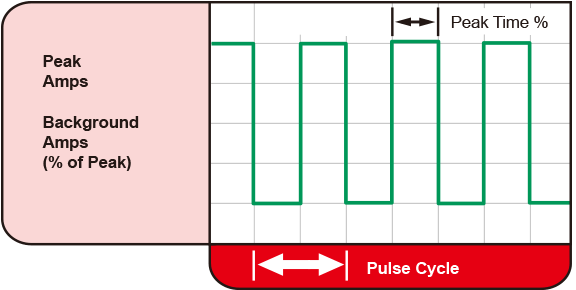

Pulse TIG

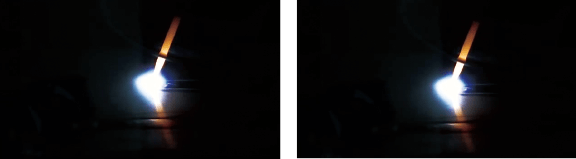

Conventional Pulsed TIG

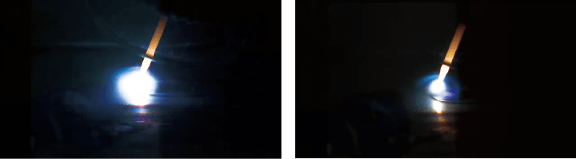

High Speed Pulsed TIG

Typically from 0.2 to 10 PPS. Provides a heating and cooling effect on the weld puddle and can reduce distortion by lowering the average amperage. This heating and cooling effect also produces a distinct ripple pattern in the weld bead. The relationship between pulse frequency and travel speed determines the distance between the ripples. Slow pulsing can also be coordinated with filler metal addition and can increase overall control of the weld puddle.

In excess of 40 PPS, Pulsed TIG becomes more audible than visible—causing increased puddle agitation for a better as-welded microstructure. Pulsing the weld current at high speeds — between a high Peak and a low Background amperage — can also constrict and focus the arc. This results in maximum arc stability, increased penetration and increased travel speeds.

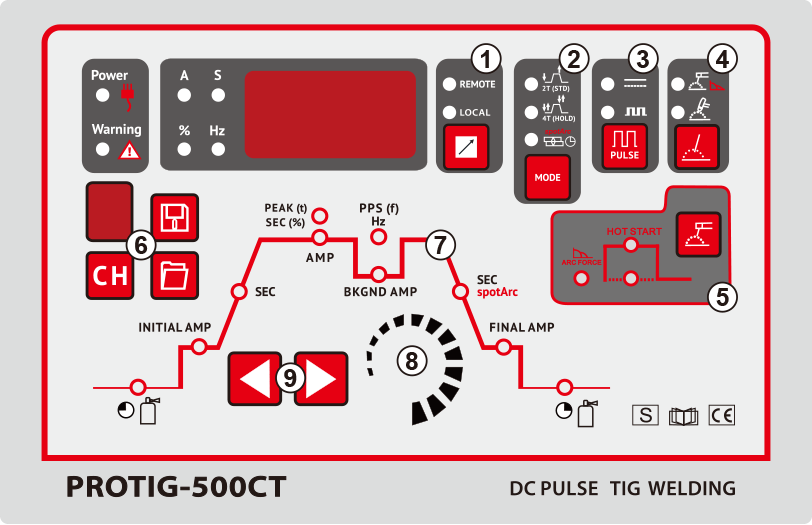

General View Of Control Panel

1. Remote: used for foot pedal or Remote torch

Local: adjusted Currents by face panel

2. 2T/4T holding mode or Spot Welding mode selection

3. Pulse ON/OFF selection

4. Process selection

5. ARC FORCE/HOT START

6. Memory with capacity of 10 sets parameters

7. Function Sequence.

8. Encoder Control

9. Select welding parameters button

LET'S STAY IN TOUCH

Get updates on sales specials and more

FOLLOW US

We want to hear from you!

Copyright © 2022 HANGZHOU TOPWELL TECHNOLOGY CO.,LTD. | 浙ICP备2022006748号